Many types of facilities rely entirely on ventilation, for example, pharmaceutical labs or laboratories working with volatile substances. Failure to maintain proper temperature, humidity, and airflow can damage laboratories or create unsafe working conditions.

Air conduct blades are large metal strips that generate airflow within ventilation systems. On the sides, these blades are held by plastic components connected to a drive mechanism within a plastic casing.

Originally made from glass-reinforced PA (polyamide), the plastic isn’t strong enough to handle high bending loads caused by strong airflow. When it eventually breaks, there is no alternative but to purchase the entire component, as it wasn’t designed for maintenance. In our case, the price of the component is €285.

Reliable On-Demand Spare Parts Production with Continuous Carbon Fiber

The parts were adapted by the Anisoprint team using the Aura 3D printing application for composite materials. Support structures were removed and the walls were reinforced by increasing their thickness. Print settings were adjusted, prioritizing durability over a smooth finish.

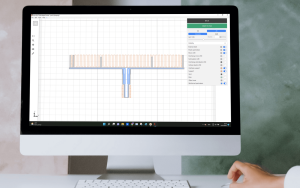

The parts were printed with Smooth PA reinforced with continuous carbon fibers (CCF). For the model in the image below, the internal plastic perimeters were removed, leaving two outer plastic layers and one continuous carbon fiber perimeter. To accommodate the fibers, the path width was reduced from 0.75 mm to 0.5 mm, and the plastic path width from 0.4 mm to 0.3 mm. This resulted in a strong component with optimal surface quality.

Reducing path width while maintaining standard line height can create excess pressure in the print chamber and cause clogs during 3D printing. To prevent this, the print height increased from 0.08 mm to 0.1 mm for the plastic, and from 0.35 mm to 0.45 mm for the fibers.

Successful Spare Part Management with 3D Printing and Continuous Carbon Fiber

Most businesses hesitate to maintain an adequate inventory of spare parts because they believe storing them contradicts cost minimization. 3D printing with composite materials helps reduce costs and ensures operational efficiency. The 3D-printed spare parts not only save money and extend maintenance intervals but are also designed to withstand greater loads.

- Result: Sustainable resource usage and significant savings: €48.1 instead of €285

- Benefits: Longer maintenance intervals, reliable and durable components, and more dependable operations ensuring worker safety and responsible storage.