Innovative 3D technologies continue to transform the landscape of industry, medicine, art, and education.

The ability to quickly and affordably create complex and precise objects opens doors to applications that were previously impossible.

This article reviews the most advanced technologies in the field of 3D printing, their applications, and their impact across various sectors.

Advanced 3D Printing Technologies

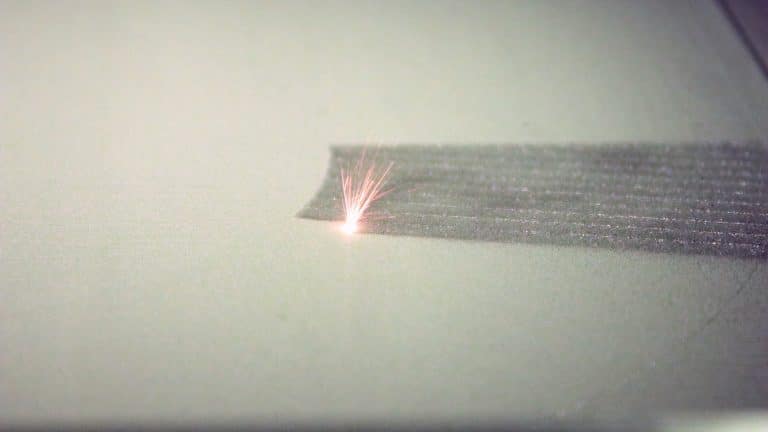

1. Advanced Metal Printing:

3D metal printing has undergone significant advancements in recent years. Israeli company Tritone, for example, has developed a unique powder-free metal printing technology. This allows for flexible product design and engineering, while also reducing production time and costs.

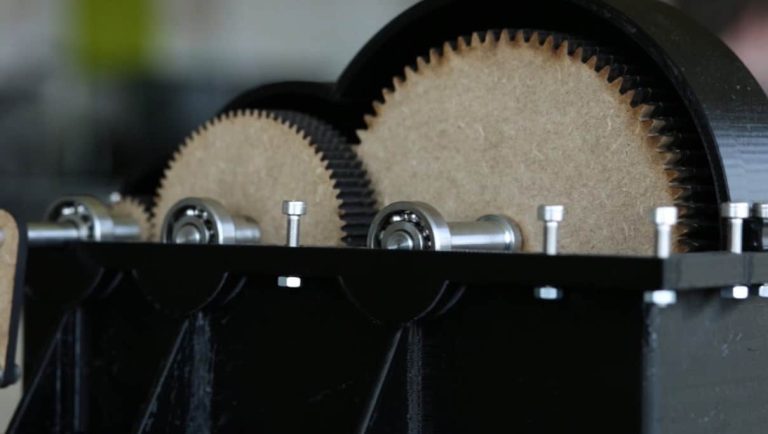

2. Composite Material Printing:

The ability to incorporate carbon fibers and other composite materials in 3D printing enables the production of parts that are both lightweight and exceptionally strong. Arevo Labs, acquired by Stratasys, developed a technology for printing parts from carbon fiber-based composites used in industries like automotive, aerospace, and cycling.

3. Advanced Polymer Printing:

Technologies such as FDM, SLA, and SLS enable the printing of advanced polymers with improved mechanical and thermal properties. Companies like Ballistic Bit offer a range of 3D printers based on these technologies, suitable for various industrial applications.

Advanced Applications of 3D Technologies

1. Automotive and Aerospace Industries

3D printing enables the production of lightweight and strong parts, reducing the weight of vehicles and aircraft and improving fuel efficiency. For instance, Tritone provides solutions for printing complex metal parts for the automotive sector.

2. Medicine

3D printing is used to produce custom implants, surgical models, and medical instruments. The use of biocompatible materials allows for implants tailored precisely to the patient.

3. Architecture and Construction

3D printing allows for the creation of precise architectural models, and even entire buildings. The technology offers time and cost savings, as well as design flexibility unmatched by traditional construction methods.

4. Art and Design

Artists and designers use 3D printing to create sculptures, jewelry, and custom products. The technology supports creative freedom and design flexibility, enabling the production of complex items that were previously unattainable.

Impact of 3D Technologies on Industry

A. Customized Production

3D printing enables the creation of personalized products quickly and affordably. In medicine, for example, patient-specific implants can be produced, improving treatment outcomes.

B. Cost and Time Efficiency

The technology allows for the production of complex parts in a single process without assembly, reducing production time and cost. Additionally, on-demand manufacturing minimizes the need for large inventories.

C. Sustainability

3D printing reduces waste during production by using only the exact amount of material needed for each part. Moreover, biodegradable and eco-friendly materials can be used, contributing to sustainability efforts.

Challenges and the Future of the Technology

A. Challenges

Despite its benefits, challenges remain, including printing speed, material costs, and the quality of printed parts. There is also a need for industry standards and regulations to ensure product quality and safety.

B. The Future of the Technology

The future promises advances in printing technologies, new materials, and integration with other technologies such as artificial intelligence and the Internet of Things. This will enable smart and automated production and unlock new applications in industry, medicine, and beyond.

Conclusion

Innovative 3D technologies continue to reshape industry and society. The ability to produce complex, customized parts quickly and affordably is unlocking new applications and improving existing processes.

As the technology continues to evolve and gain adoption, we can expect significant changes across many sectors and a positive impact on the economy and society at large.