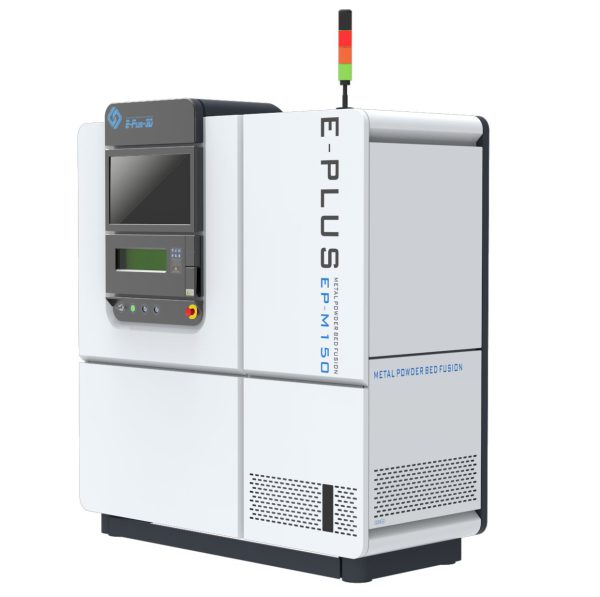

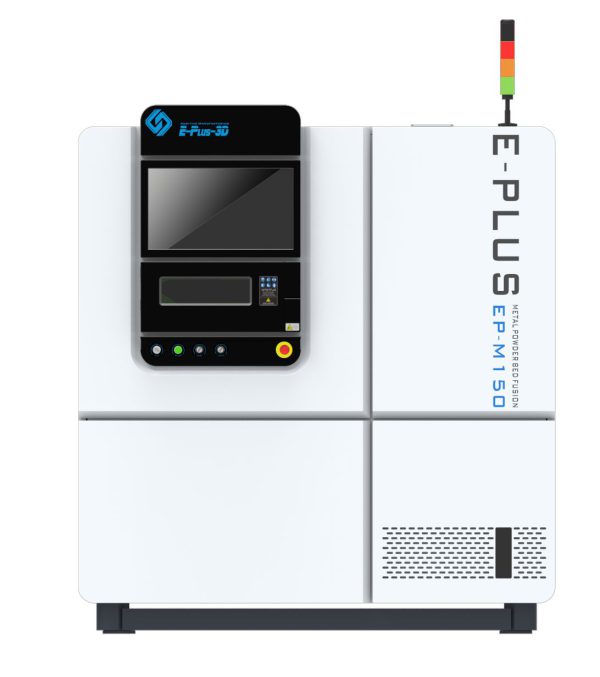

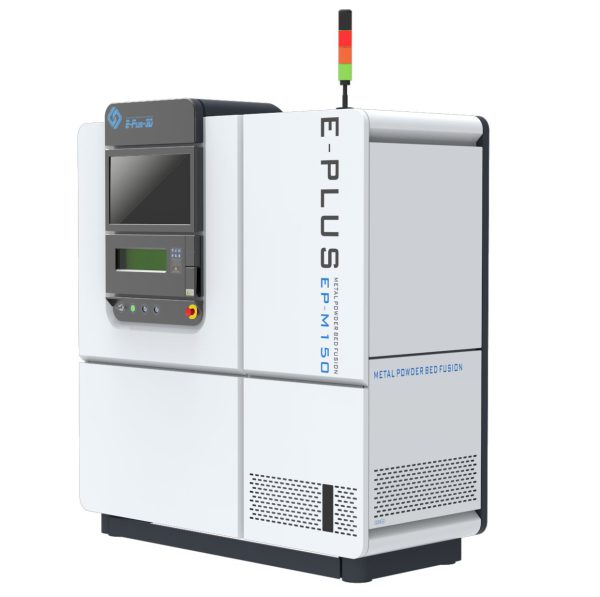

High Compact & High Precision Metal Additive Manufacturing Equipment

Home » 3D Hardware » Eplus3D » EP-M150 Metal 3D Printer

The EP-M150 3D Printer is compatible with most popular metal powder materials, including titanium alloy, aluminium alloy, nickel-based superalloy, Maraging steel, stainless steel, Cobalt, chromium alloy. Well suited for applications such as, medical, education, dental, materials development and industrial manufacturing. Using MPBF ™ technology, (Metal Powder Bed Fusion), combined with single and dual-laser printing modes with 200 and 500watts laser element, making a perfect solution for high performance, precision parts, rapid mass production.

It offers very High Precision High laser, with accurate beam quality, tiny laser spot, High consistency and uniform laser beam, consistent laser quality at any spot of the building platform. The density of printed parts can reach nearly 100 %. In dual laser printing mode, precision deviation in alignment area ≤ 0.15 mm.

Layer thickness can reach up to 100 μm, while combining dual-laser elements with large layer thickness mode can speed printing performance up to 2.3 ~ 2.7 times faster.

The EP-M150 offers High consistency across wide verity of compatible machines, using same process parameters. Intuitive and user-friendly software featuring One-click printing. Maintenance of replacement filters and material refilling can be completed within 2 minutes. Minimal material waste, unused leftovers can be collected and reused in the next print job.

1734

Machine Model | EP-M150 |

Build Chamber (XxYxZ) | Φ150 mm x 140 mm (Φ 5.91 x 5.51 in) (height incl. build plate) |

Optical System | Fiber Laser, 200 W / 500 W (single or dual-laser optional) |

Spot Size | 40~60 μm |

Max Scan Speed | 8 m/s |

Layer Thickness | Up to 35 cm³/h |

Theoretical Printspeed | 200 W laser: 20~50 μm 500 W laser: 20~100 μm |

Material | Titanium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | - |

Power Supply | 220 V, 3 kW, 14 A, 50 ~ 60 Hz (Dual laser : 5.8 kW, 19 A) |

Gas Supply | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm |

Dimension (WxDxH) | 1750 x 799 x 1828 mm |

Weight | 900 kg |

Software | EP Control, EP-Hatch |

Input Data Format | STL or other Convertible File |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up