Depowdering system for automated powder removal of metal laser-melted parts

Home » Post Process » Solukon » SFM-AT1000-S

The SFM-AT1000-S is an upscale of the well established SFM-AT800-S and optimized for automatic depowdering of parts with an extraordinary height of up to 1.000 mm.

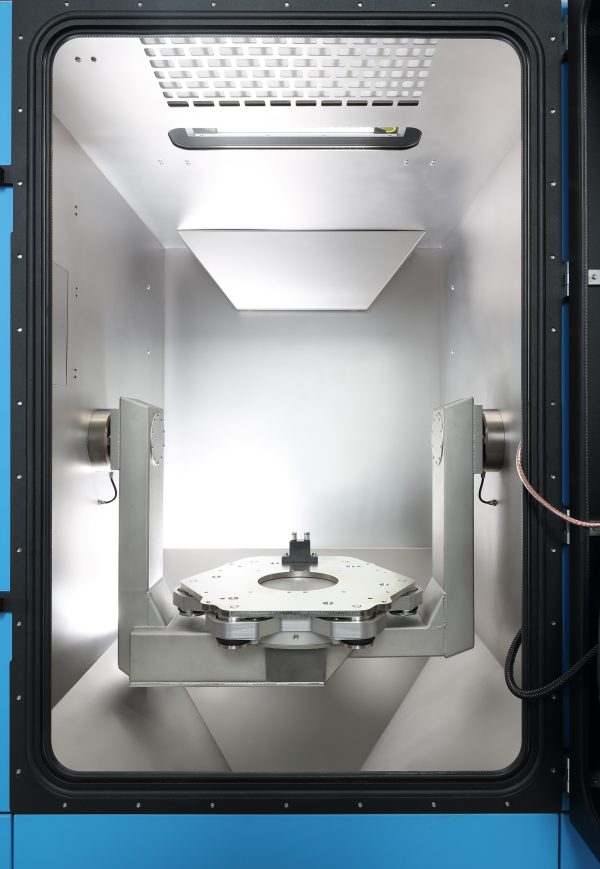

The SFM-AT1000-S cleans metal laser melted parts within a sealed process chamber, with targeted vibration and automated two-axis rotation.

The state-of-the art design is specialized in the requirements of cleaning extraordinary high and complex parts like modern compact rocket-propulsion engines.

The depowdering system is based on the unique Solukon Smart Powder Recuperation® technology.

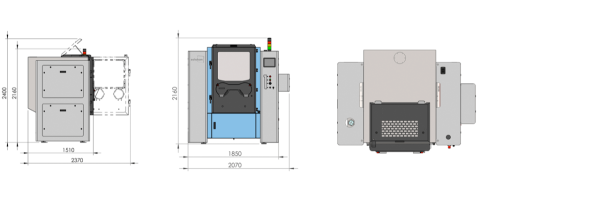

Installation space (W x D x H) | 3,500 x 2,500 x 3,000 mm |

Weight | 900 kg |

Mains voltage / frequency | 400 / 50 - 60 V / Hz |

Power consumption | 1.5 kW |

Power supply | 16 A |

WhatsApp us

Thanks for signing up