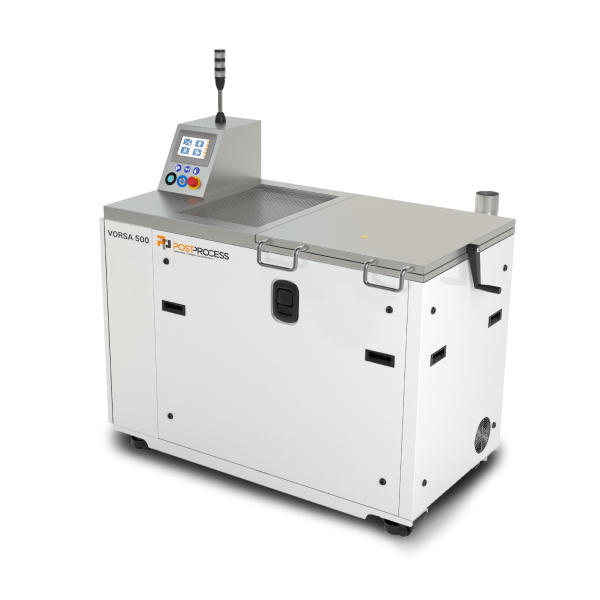

FDM Support Removal with Precision and Efficiency

Home » Post Process » Post Process Technologies » VORSA 500

The PostProcess® VORSA™ FDM support removal solution boasts an expansive work area and consistently delivers high-quality results for all parts, regardless of their geometry, while maintaining short cycle times to meet your high-volume production demands. The VORSA 500 excels in both delicate and robust support removal, offering enhanced throughput through the innovative patented Volumetric Velocity Dispersion (VVD) technology, which guarantees comprehensive part coverage and support removal. Employing multidimensional spray technology, the VORSA 500 ensures rapid drying times without compromising the integrity of the parts, preventing them from becoming oversaturated with detergent.

This unique system stands as the world’s only combination of specialized hardware designed for 3D post-printing, customized software, and additive-formulated consumables. With our exclusive Agitation Algorithms, which precisely control energy and detergent flow, the PostProcess VORSA consistently achieves hands-free support removal from 3D printed FDM parts.

Hardware Features: |

|

Size and Weight: |

|

AUTOMAT3D® Software Features: |

|

Electrical – US: |

|

Safety Features: |

|

WhatsApp us

Thanks for signing up