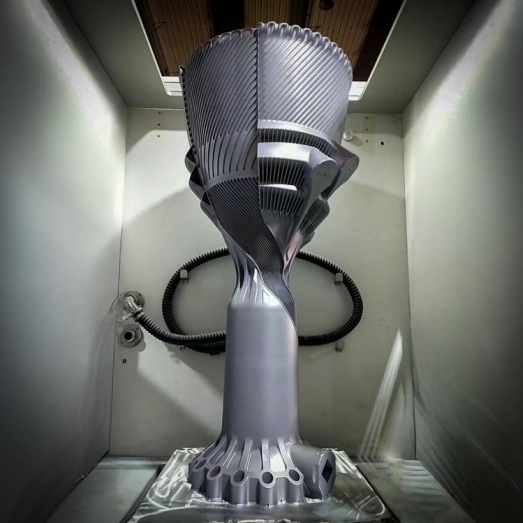

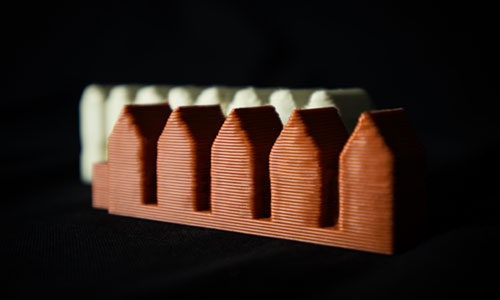

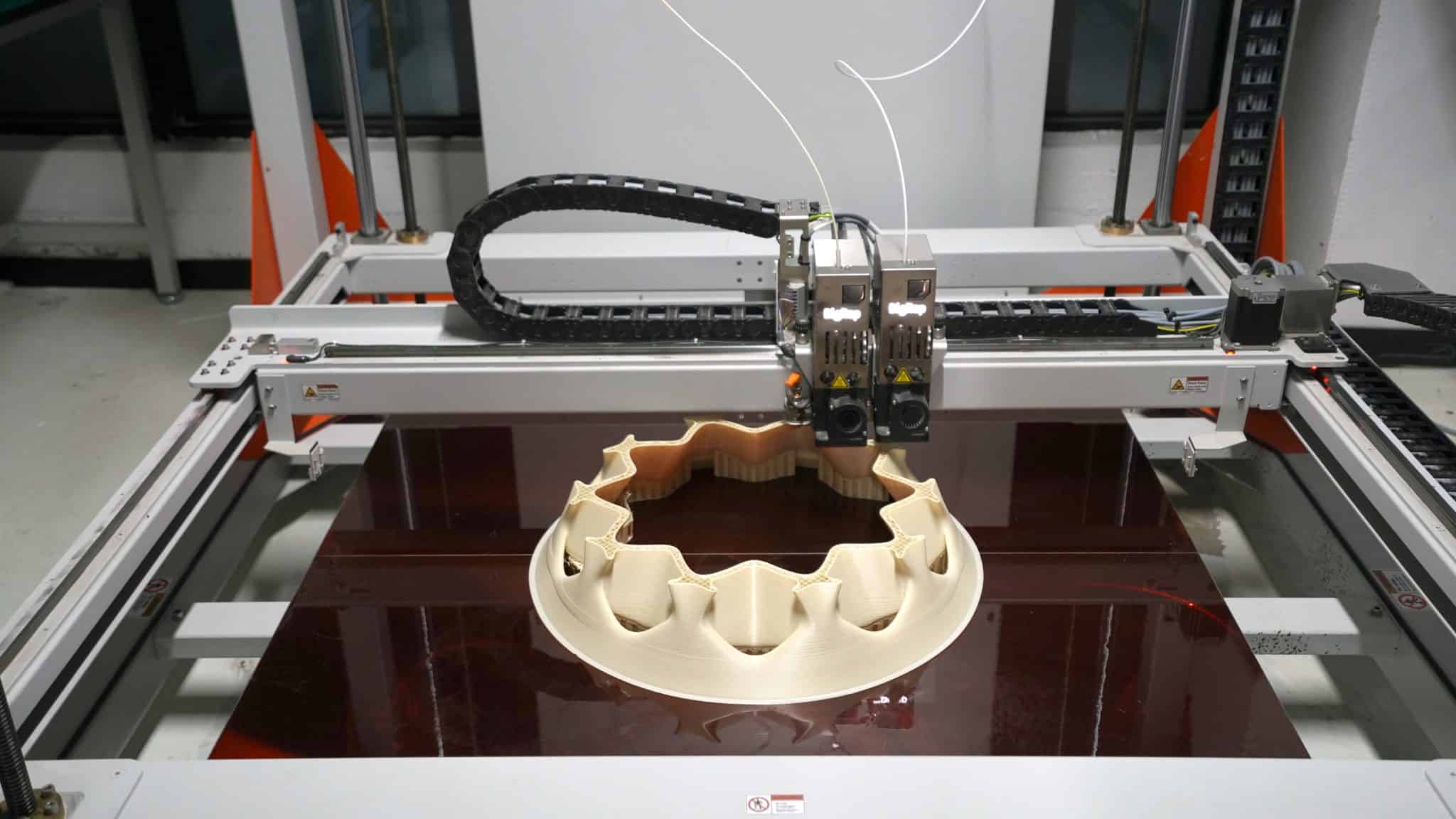

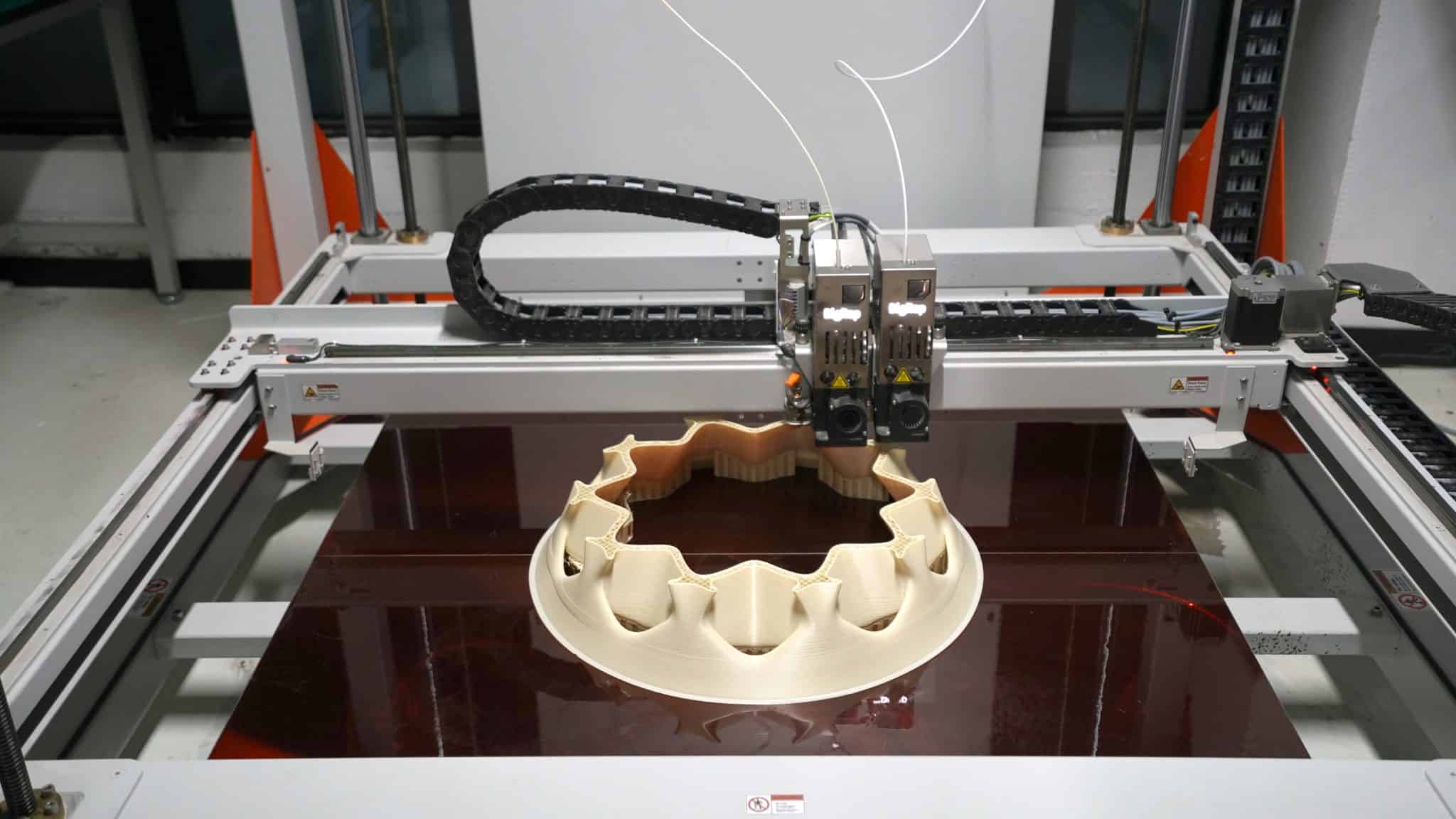

Large Format 3D printing capability offers a unique advantage to the Auto and Aviation industries to produce large format prototyping at a 1:1 scale. Large format prints can shorten the development turnaround time to a fraction comparted to traditional methods.

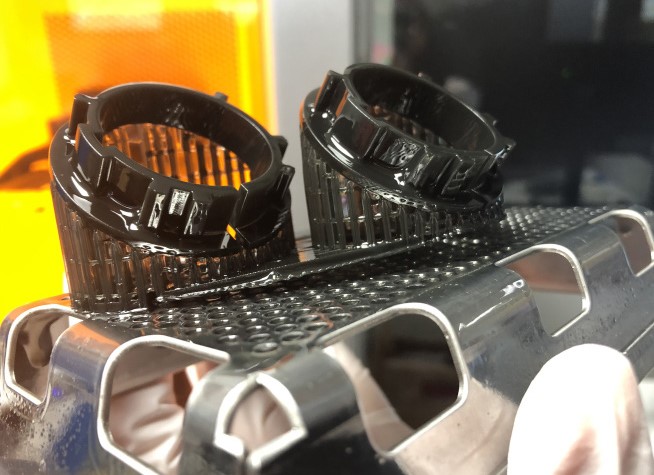

Within a day, designers can examine and simulate advanced 3D printed parts and carry out the required verification tests, quickly and effectively. Wide variety of 3D printing surface finish is available to integrate the part with minimal difficulty.

Contact us for advice!

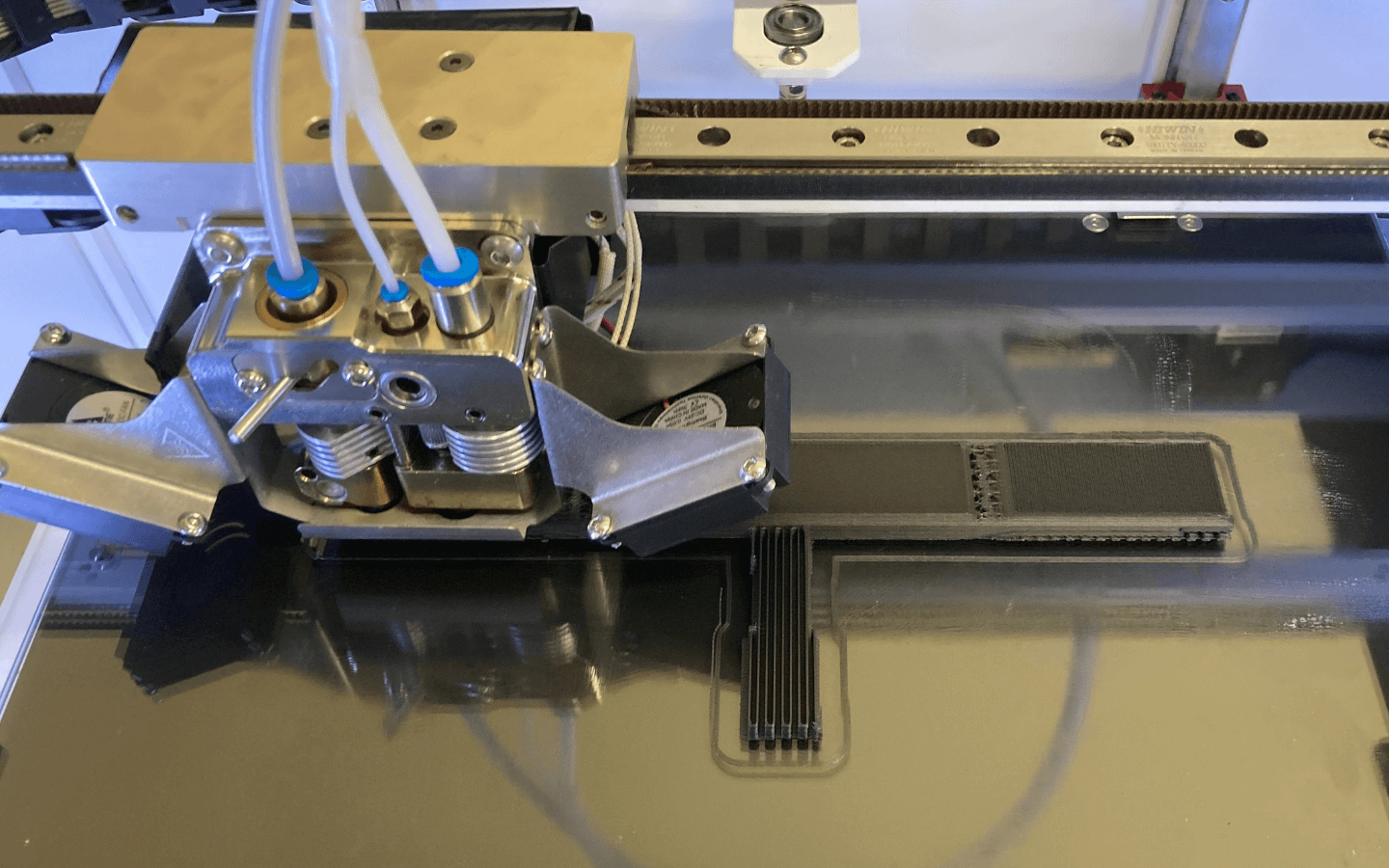

As a LFAM (large format additive manufacturing) 3D printing equipment distributor, Ballistic Bit has the most experience and most suitable large format additive manufacturing solutions.

In compare to the high investment associated with traditional tooling, Large-scale additive manufacturing (AM) deliver cost efficiencies along with better quality and accuracy.

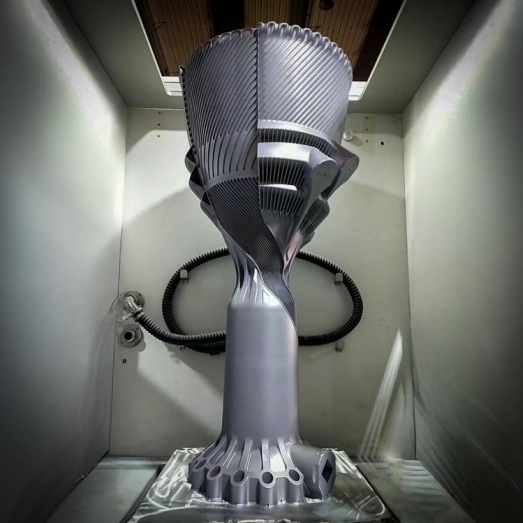

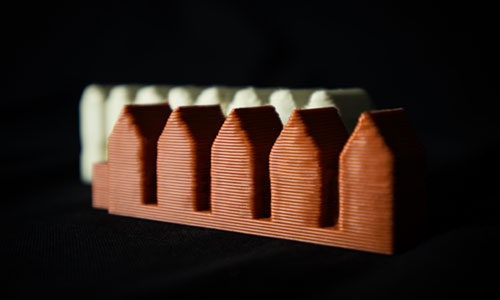

Large-scale AM technology is more accessible for companies to deploy on a production basis, due to advances in metals & polymers 3D printing technology and workflow software along with new materials (Materials for 3D printing) and lower-cost printer options are making.

That’s especially important as part of marketing and distribution efforts ramp up and customer demands.

Companies in several industries like aerospace and automotive are beginning to understand the value in trading up traditional manufacturing practices for large-scale AM technologies.

The ability to 3D print large parts either in-house or through a specialized AM solutions company, significantly shortens & introduce significant savings, like waiting for a third-party player to create custom tooling, or shipping parts overseas for production.

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up