Simplify production, scheduling, and resource management in a unified platform.

- Base manufacturing and business decisions on real-time insights.

- Maintain optimal inventory levels consistently.

- Prioritize production considering people, machine, and material availability.

- Enhance shop floor management with task-level control.

- Free up employees by automating workflows.

- Automate cost calculations to align with your operations and customer requirements.

Customize automation processes to match your business parameters.

- Automate routine tasks with simple workflows.

- Use a variety of automation tools.

- Make your digital business more efficient.

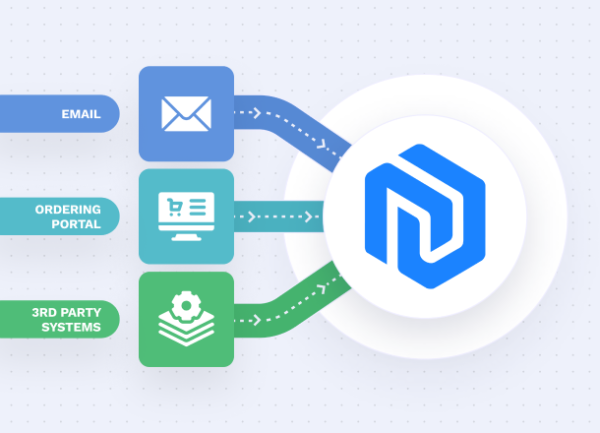

Combine B2B orders with incoming sales channels.

- Gather job and quote requests from various channels in a single location.

- Connect email inboxes, websites, and over 500 other systems.

- Send quotes and approval requests digitally.

- Quickly estimate manufacturing times and costs.

- Offer a dedicated online portal for improved customer service.

- Integrate invoicing and B2B payment procedures.

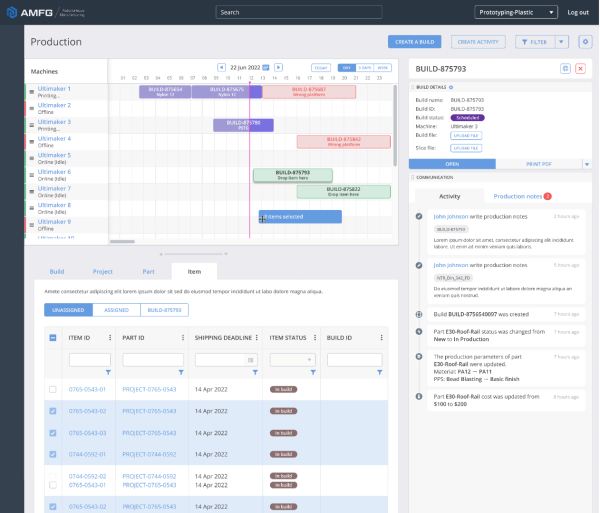

Ensure secure control at the floor level, covering scheduling, production, and logistics.

- Plan and monitor production operations.

- Access manufacturing tasks and ingredient lists for each task.

- Add and review production notes.

- Track resource consumption through real-time material tracking.

- Assign and reassign jobs to operators.

- Utilize barcode scanning to monitor and complete tasks.

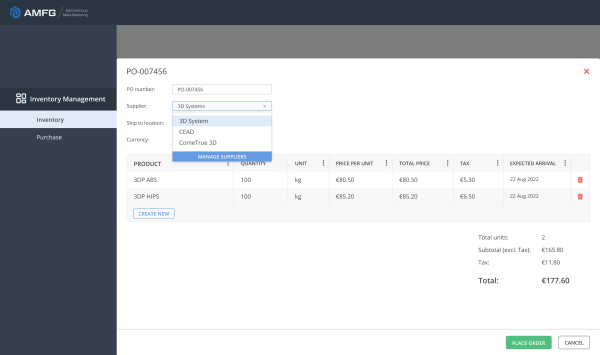

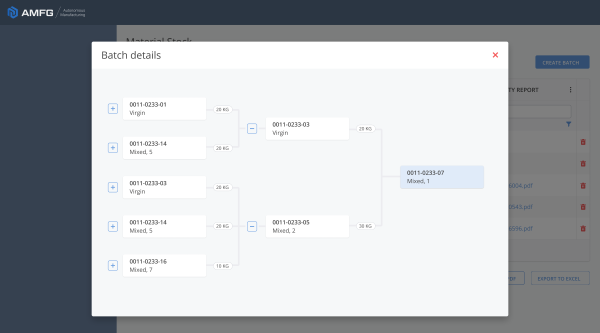

Access real-time inventory optimization and manage your stock needs.

- Take full control of finished products and raw materials in your inventory.

- Automate reordering to avoid stock-outs.

- Handle product variants and materials in a centralized system.

- Keep track of your inventory across multiple warehouses.

Ensure production quality and compliance control.

- Monitor tasks related to quality assurance.

- Track instances of part non-conformance.

- Automatically monitor re-production processes for faulty parts.

- Achieve end-to-end traceability of production workflows.

Efficiently schedule and plan production to make the most of your resources.

- Manage your schedule using real-time data.

- Make flexible scheduling adjustments easily with drag and drop.

- Implement fully automated scheduling routines.

- Plan maintenance activities.

- Track progress with a live floor-level production status overview.

Get a complete record of production jobs, materials, machines, workers, and more, down to the task level.

- Get detailed tracking of all production and operation activities from start to finish.

- Monitor changes to jobs, files, machines, materials, deadlines, and quotes.

- Find items across production centers, departments, and teams.

Establish smooth integration and collaboration with subcontractors.

- Access real-time updates on production jobs with subcontractors.

- Effortlessly connect with OEM clients and subcontractors.

- Conduct transactions directly with subcontractors.

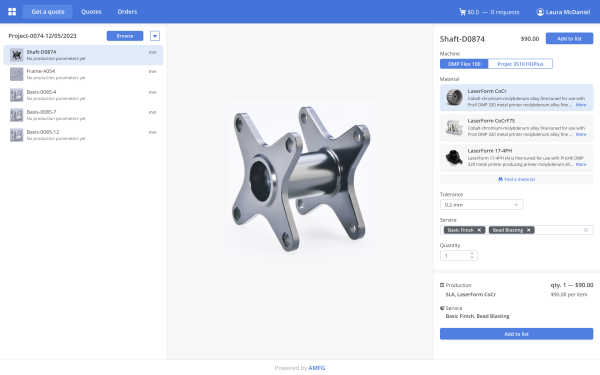

Quickly estimate production costs with precision and control.

- Utilize adaptable costing templates that suit your business needs.

- Access detailed cost breakdowns considering over 50 variables, including CAD files, machine costs, and material costs.

- Select from a variety of costing templates in the library.

- Benefit from expert support provided by AMFG’s costing consulting team.

Monitor and control your machines from a distance.

- Keep track of your machines in real time.

- Send status alerts to users and adjust builds based on machine status.

- Securely stream data to machines.

- Establish two-way integration with production machines.

- Use flexible adapters to integrate with new machines.

Access a 500+ integration layer with ready-to-use connections to CAD, PLM, BI, machines, and more.

- Browse a diverse library of pre-built integrations.

- Align with your existing processes using our integration layer for CAD, PLM, CRM, accounting, ERP, and more.

- Develop new integrations with third-party software.

- Get support from AMFG’s integration team.