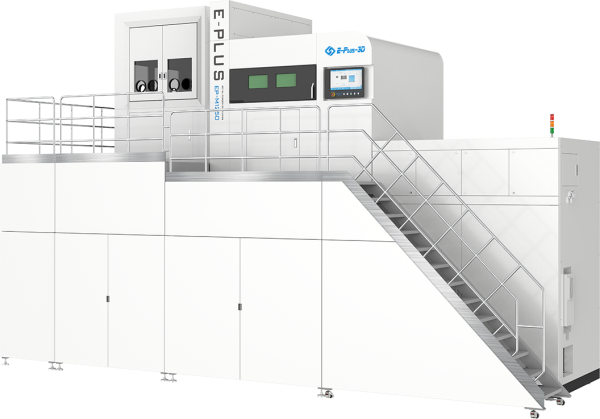

Redefining Precision Manufacturing with MPBF Excellence

Home » 3D Hardware » Eplus3D » EP-M1250 Metal 3D Printer

Utilizing MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 boasts an impressive 1250 x 1250 x 1350 mm build envelope and incorporates nine laser systems, ensuring highly efficient production. Its precision positioning and innovative area splicing control technology guarantee consistency and stability throughout the entire printing process.

This versatile system accommodates a wide range of metal powders, including titanium, aluminum, nickel-based alloys, maraging steel, stainless steel, chrome cobalt alloys, and more. It is ideally suited for the direct manufacturing of large, high-precision, and high-performance components across industries such as aerospace, aviation, automotive, machinery, and oil & gas.

Machine Model | EP-M1250 |

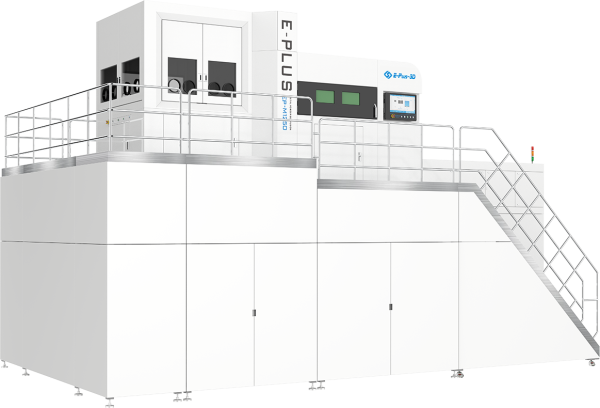

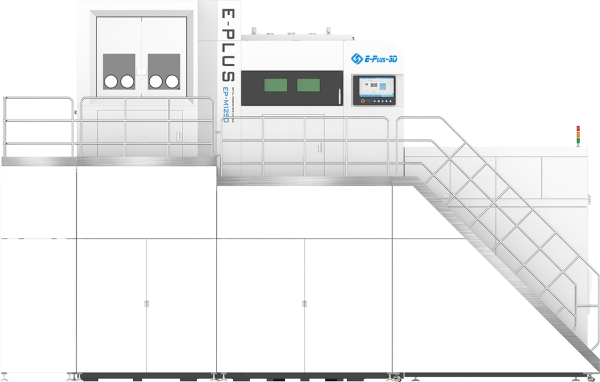

Build Chamber (XxYxZ) | 1558 x 1558 x 1200 mm (61.34 x 61.34 x 47.24 in) (height can be customized to 2000 mm) (height incl. build plate) |

Optical System | Fiber Laser 9 x 500 W / 700 W / 1000 W |

Spot Size | 70~120 µm |

Max Scan Speed | 8 m/s |

Layer Thickness | 20~120 µm |

Theoretical Printspeed | Up to 370 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | Substrate heating temperature 200 ℃ |

Power Supply | 380 V, 100 A, 40 kW, 50/60 Hz |

Gas Supply | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm |

Dimension (WxDxH) | 9000 x 4800 x 6300 mm |

Weight | 50000 kg |

Software | EP-Hatch , EP Control |

Input Data Format | STL file or other convertible format |

WhatsApp us

Thanks for signing up