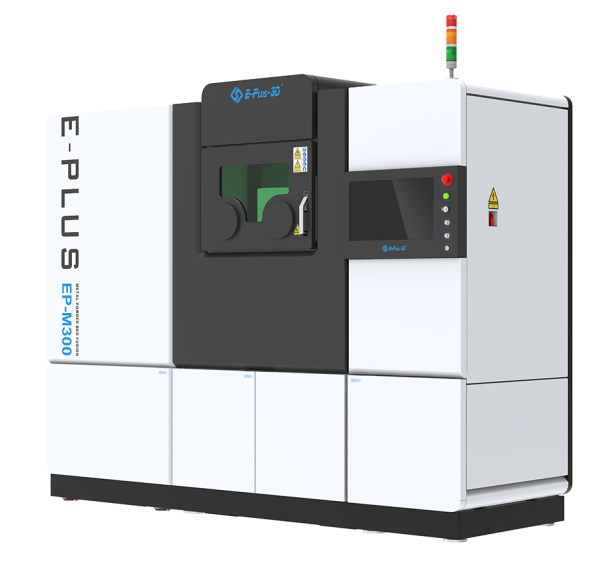

High Productivity Metal AM Machine Metal Powder Bed Fusion

Home » 3D Hardware » Eplus3D » EP-M300 Metal 3D Printer

With a print volume of 305x305x450mm, the EP-M300, adopting MPBF TM technology, is ready for production of reliable, high quality large metallic parts on an industrial scale. The EP-M300 features a steady and reliable print platform capable of printing highly dense and accurate parts.

Featuring a large print volume with single or optional dual-lasers for fast 3d prints at max print speed of up to 8m/s. Using custom build E-Plus control software, featuring one-click print or, for advanced users, options to control laser power, scan speed and direction as well as other parameters, allowing specific print optimization and for the integration of new print materials.

An intelligent slicing system, based on 3d part geometry, intelligently divided the model into discrete sections, producing optimized high part details whiles speeding printing time. The EP-M300 incorporates selected Optical elements to generate parts with minimal deviation from original CAD model due to optimized gas-controlled flow and real-time printing system monitoring.

Machine Model | EP-M300 |

Build Chamber (XxYxZ) | 300 x 300 x 450 mm (11.81 x 11.81 x 17.72 in)(height incl. build plate) |

Optical System | Fiber Laser, 500 W / 1000 W (single or dual-laser optional) |

Spot Size | 70~120 µm |

Max Scan Speed | 8 m/s |

Layer Thickness | 20~120 µm |

Theoretical Printspeed | Up to 95 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | - |

WhatsApp us

Thanks for signing up