High-Performance Component Manufacturing

Home » 3D Hardware » Eplus3D » EP-M825

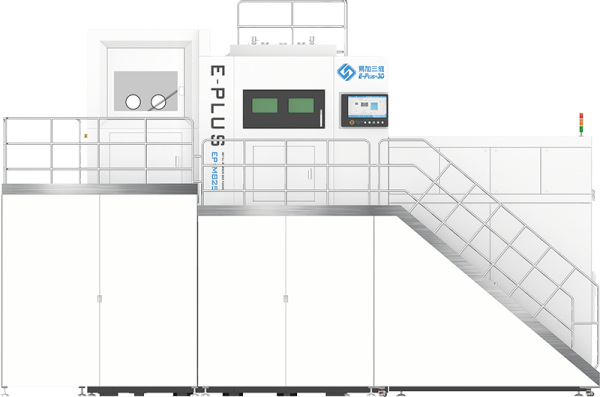

EP-M825 employs a spacious building envelope and a ten-laser system to guarantee highly efficient production. Its precise positioning, coupled with innovative area splicing control technology, ensures uniformity and stability throughout the entire printing process.

With a maximum building speed of up to 410 cm³/h, it is well-suited for the direct manufacturing of high-performance components used in aerospace, mold manufacturing, the automotive industry, and more.

Machine Model | EP-M825 |

Build Chamber (XxYxZ) | 833 x 833 x 1100 mm (32.8 x 32.8 x 43.3 in) (height incl. build plate) |

Optical System | Fiber Laser 4 / 6 / 8 / 10 x 500 W / 700 W |

Spot Size | 70~120 µm |

Max Scan Speed | 8 m/s |

Layer Thickness | 20~120 µm |

Theoretical Printspeed | Up to 410 cm³/h |

Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

Substrate heating | - |

Power Supply | 380 V, 60~100 A, 50 / 60 Hz, 25 ~ 38 kW |

Gas Supply | Ar / N₂ |

Forming chamber oxygen content | ≤100 ppm |

Dimension (WxDxH) | 8290 x 4690 x 5470 mm |

Weight | 35000 kg |

Software | EP Control, EP-Hatch |

Input Data Format | STL file or other convertible format |

WhatsApp us

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up