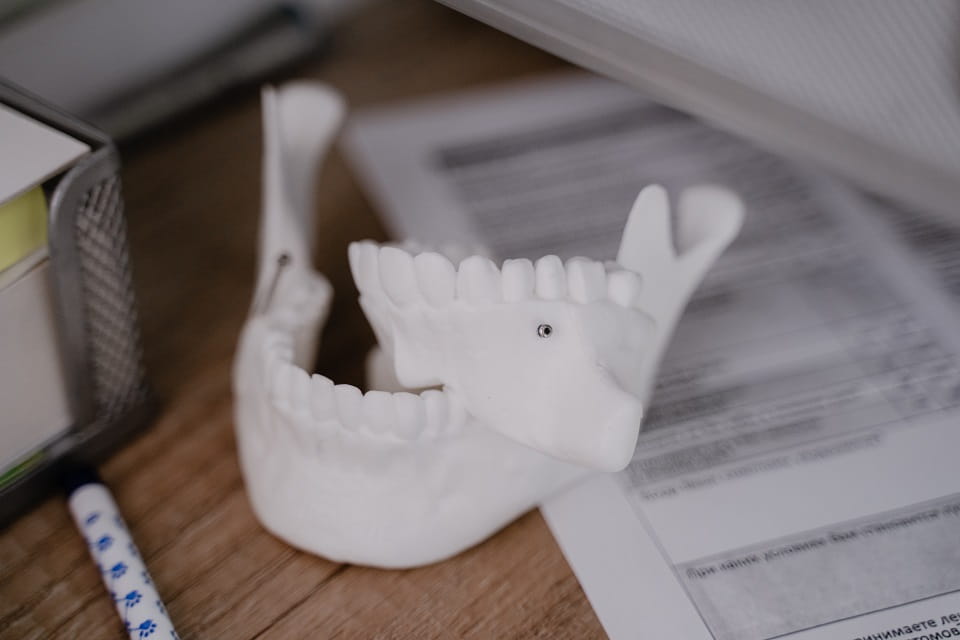

In general, 3D printers are capable of unlocking the imagination of all youngsters, and act as an effective catalyst to develop their creative talents. In general, 3D printers are capable of unlocking the imagination of all youngsters, and act as an effective catalyst to develop their creative talents.

3D printers are common in schools and universities alike, as well as within the research & development sector, public and private. It offers users:

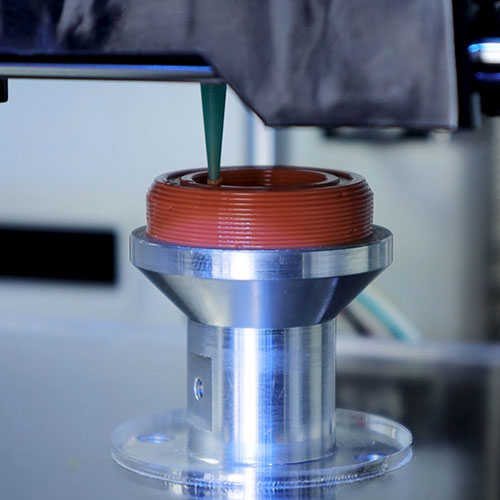

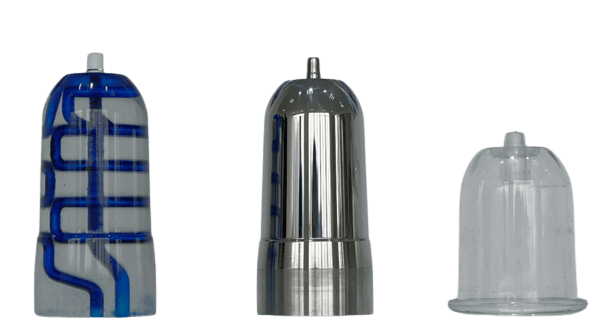

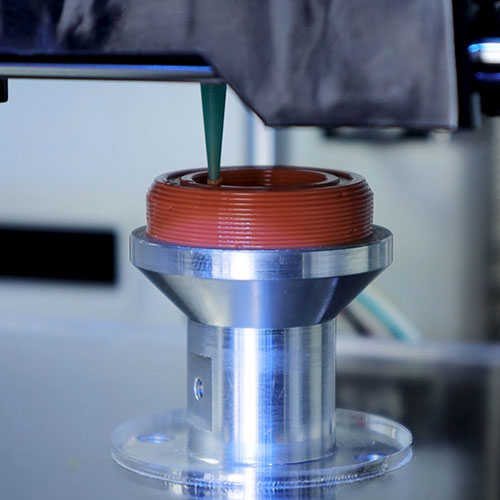

Ballistic Bit offers the option of closed and open 3D printers, and will help the customer choose the best option to suit his needs. An open 3D printer, is one that can use any print material chosen by the customer, while a closed 3D printer will only use manufacturer approved material. 3D Printers with multiple extruders can produce a rigid and/or flexible part or integrating both materials within a single part, for added strength and light weight.

Contact us for advice!

WhatsApp us

Thanks for signing up