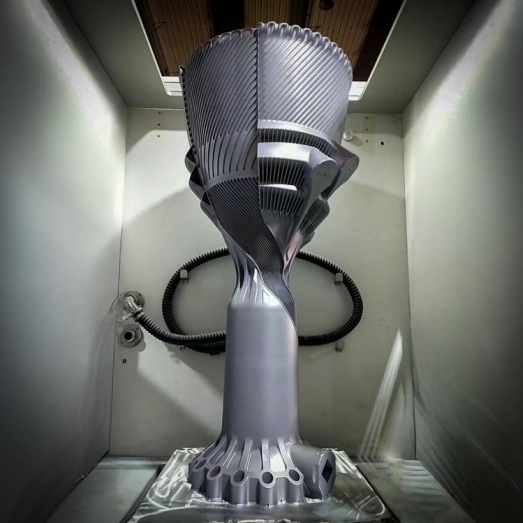

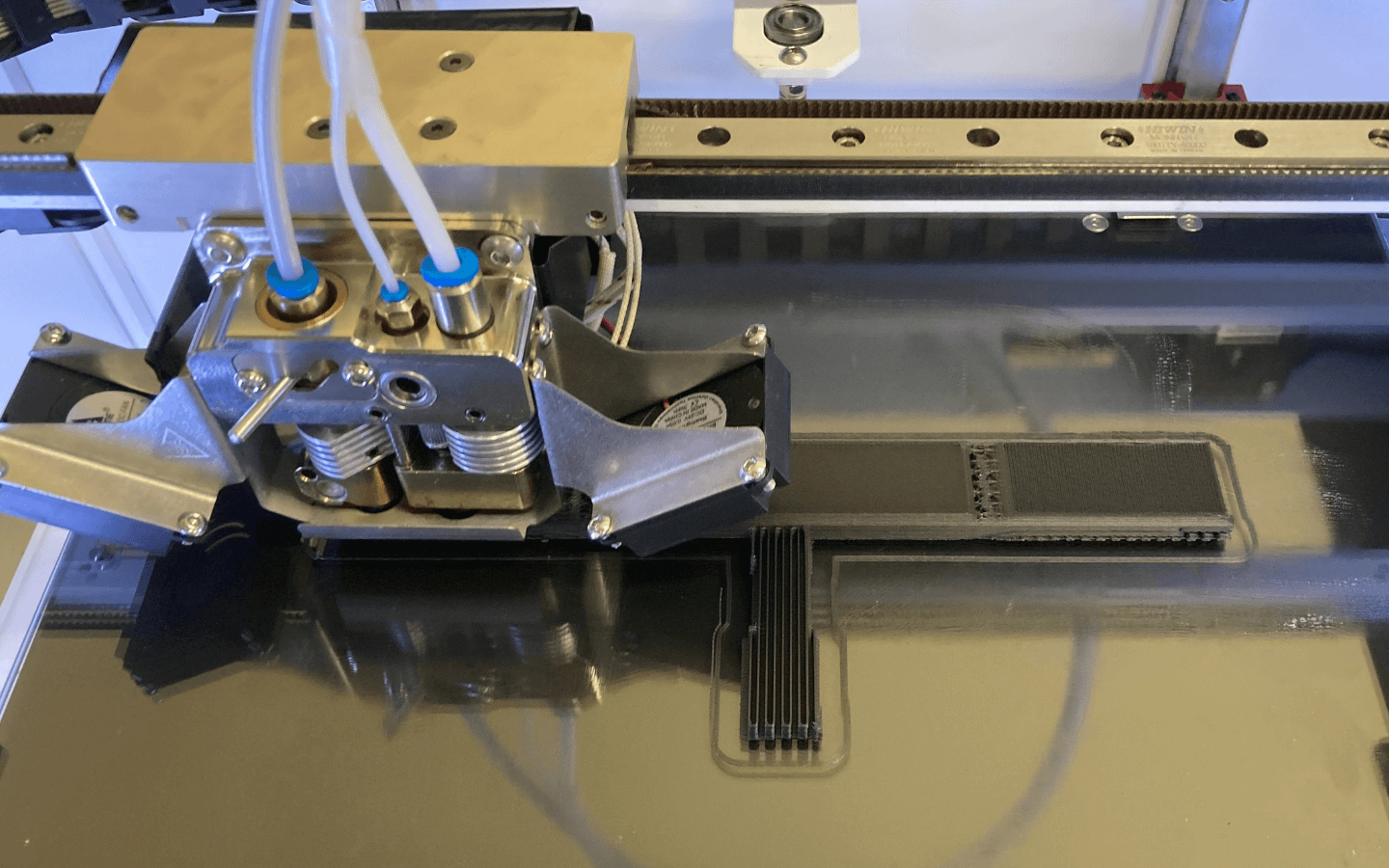

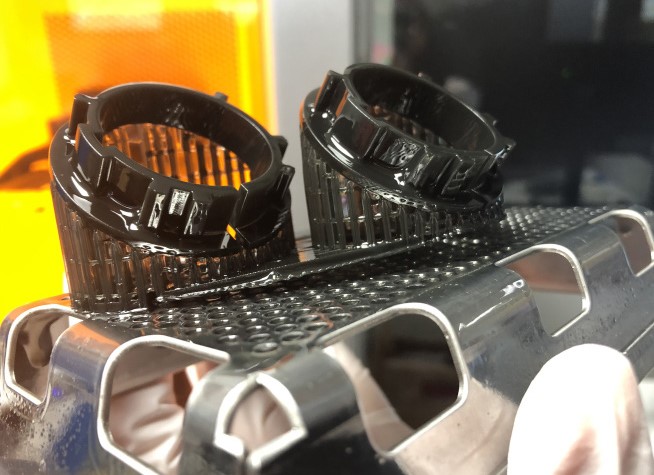

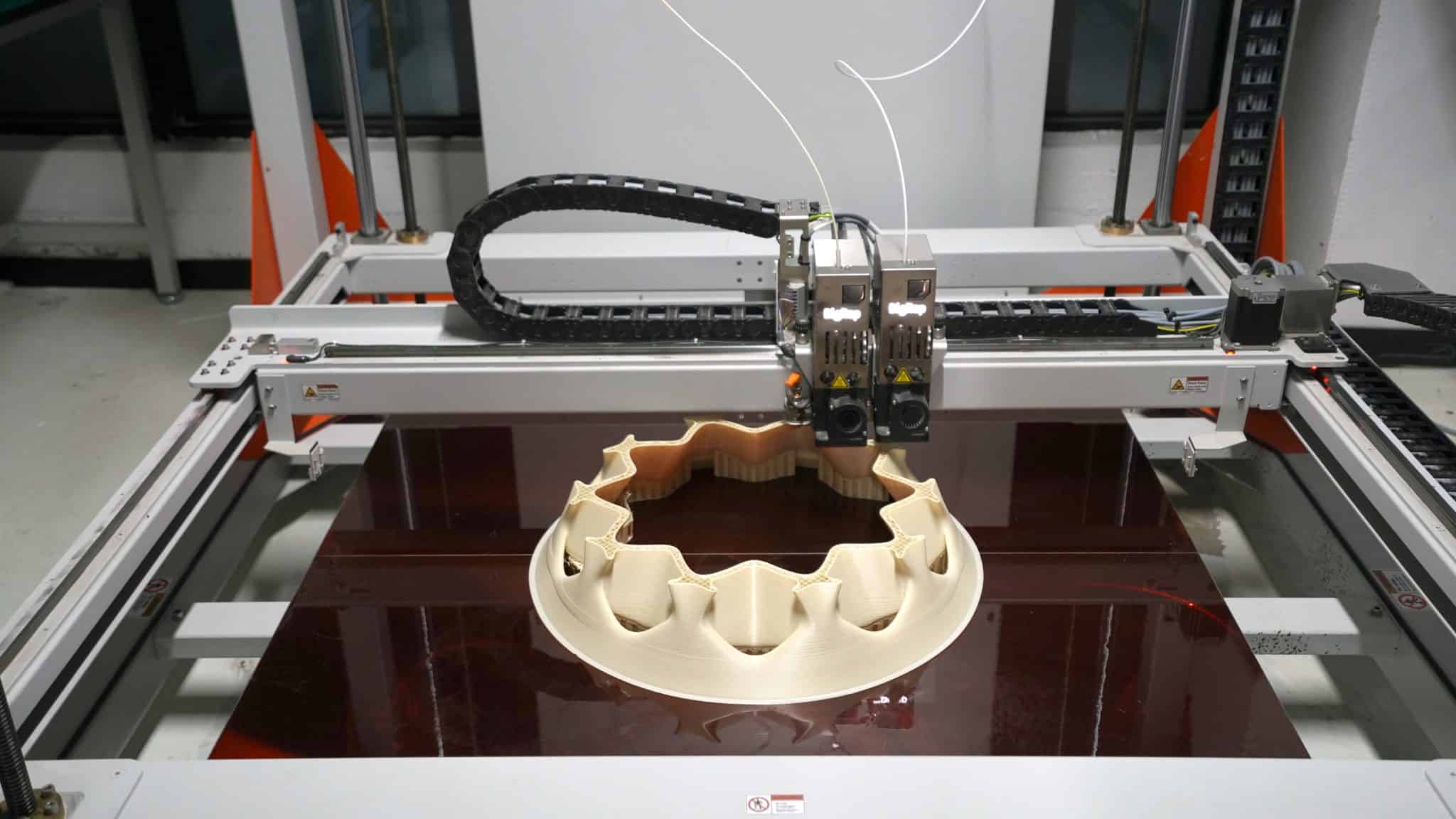

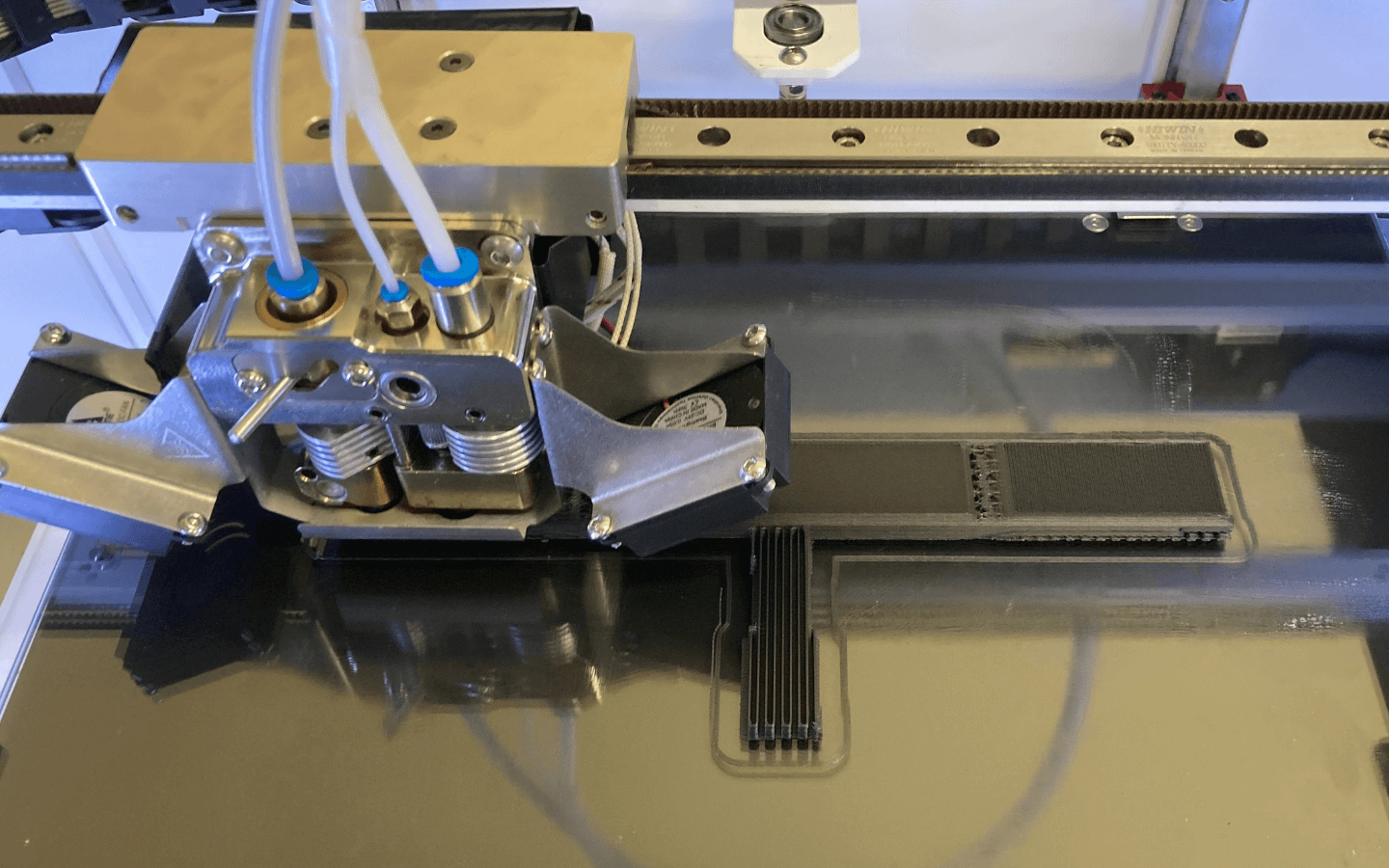

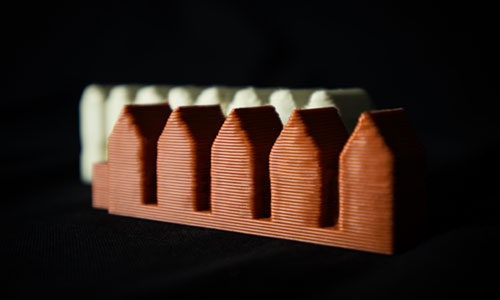

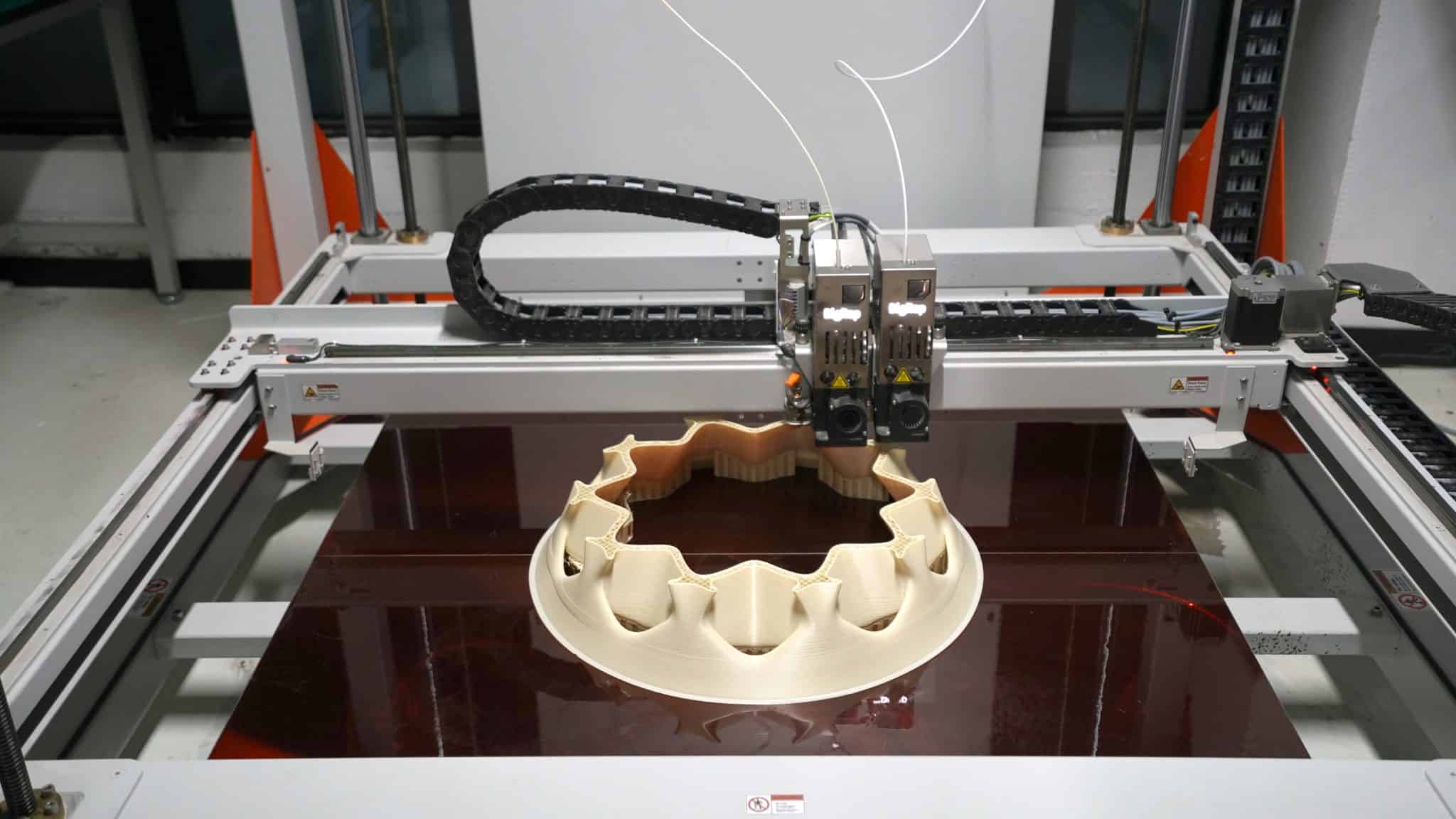

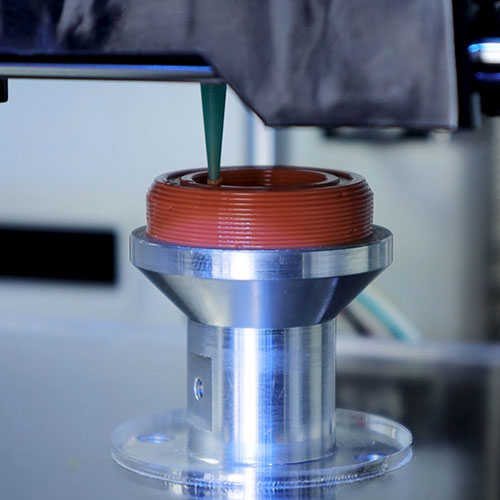

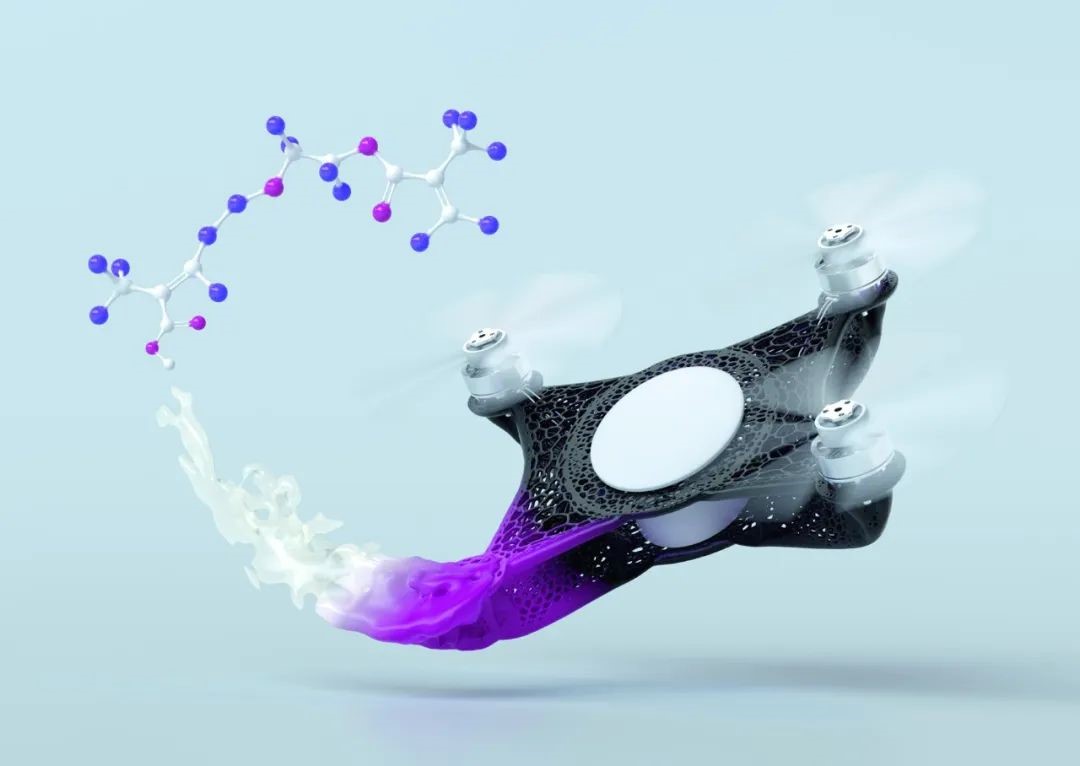

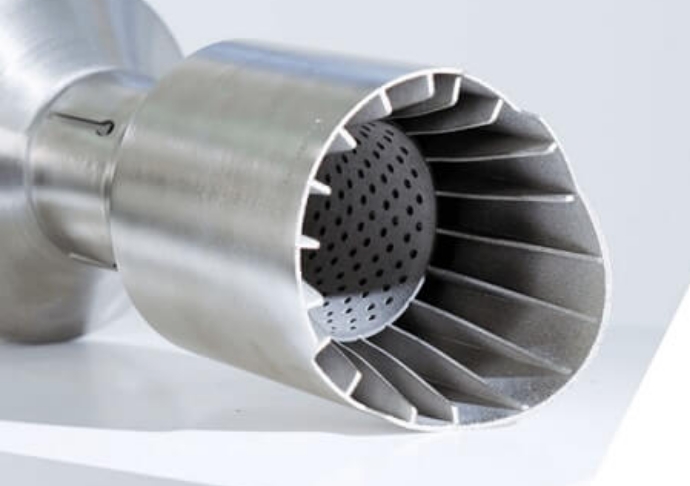

Advanced Additive Technology offered by Ballistic Bit opens the door to manufacture efficient tools of equal or better than the currently available designs. Designers can new add more complexity and functionality to old current designs, making them better and optimized to their specific tasks. Using advance materials, like carbon, can further increase strength while reducing weight. Ballistic-Bit offers 3D Printers from Anisoprint cap bale of using advanced materials for 3D printing.

Contact us for advice!

WhatsApp us

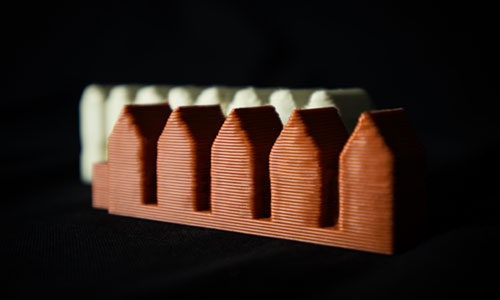

טכנולוגיית הדפסת תלת מימד מחוללת מהפכה בתעשיות מרובות בכך שהיא אפשרה השגת מטרות מהירה, התאמה אישית וייצור חסכוני.

לסיכום: הרבגוניות והיעילות של הדפסת תלת מימד הופכות אותה לנכס בעל ערך על פני מגזרים מגוונים, מה שמניע חדשנות ומשפר את יכולות הייצור.

Thanks for signing up